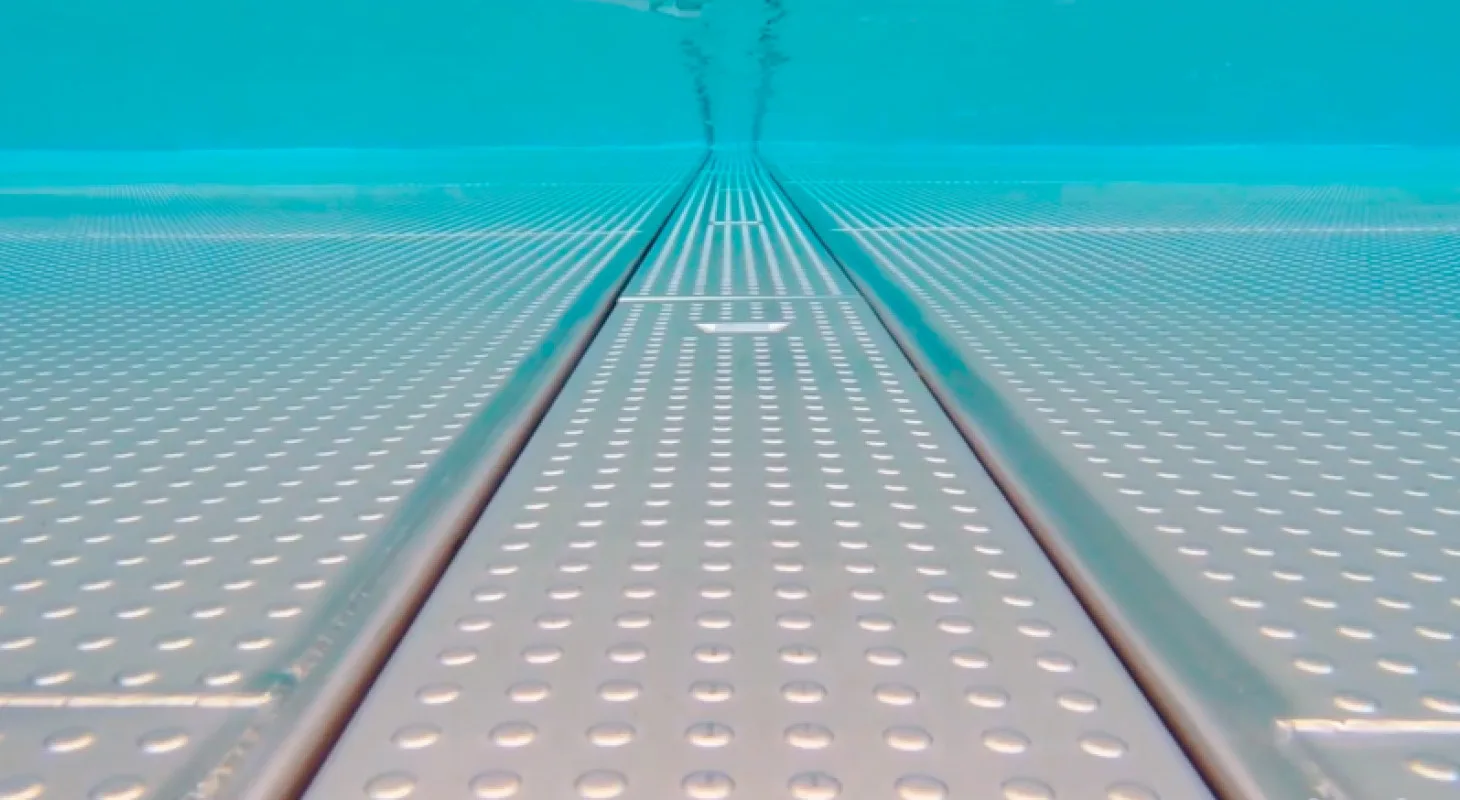

Edelstahl ist der hochwertigste, edelste Baustoff.

Langlebigkeit und Qualität sind für Synonyme für Nachhaltigkeit. Nur höchste Qualität der verwendeten Materialien gepaart mit handwerklicher und technischer Exzellenz unserer MitarbeiterInnen garantiert die Einsatzdauer unserer Becken von 50 Jahren und darüber hinaus. Daher setzen wir auf Eigenausbildung unserer Mitarbeiter und Investitionen in modernste Fertigungstechnologien. Und wenn Sie in 31 Jahren den Wunsch verspüren Ihr hsb-Becken an geänderte Nutzervorlieben anpassen zu wollen, bauen wir Ihnen ihr Becken auch gerne wieder um.